The manufacturing and construction industries have faced unique difficulties during the global pandemic, mostly due to the inability to work from home. The health and safety of employees will continue to be a focus, and the industries will begin reevaluating operations and processes using technology to reduce risks, save money, and increase efficiency. We can see how technology continues to be a huge asset for every industry, including manufacturing and construction.

#1 – COVID-19 Adaptations and Employee Safety

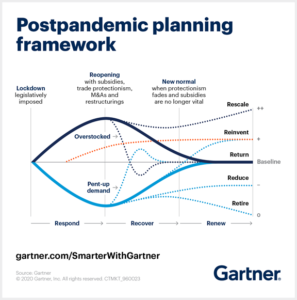

Manufacturing and construction industries will begin to reevaluate their workforce and operations to follow health guidelines and save money. Many companies will begin to place more responsibilities on a single department to dissolve another to save money. Another reason for reevaluating the workforce and processes is to prepare for other disaster recoveries as the industries work through their yearly plan. By August of last year, “750,000 jobs in the manufacturing sector were lost.”

#2 – Reevaluating the Workforce

The total job loss caused by the pandemic has not been regained. The industrial sector has a lot to recover from after the impacts of the global pandemic. “61% of surveyed executives are planning to develop a hybrid model for their production and non-production processes over the next three years.” Investing more into skilled workers who are data driven and/or tech-savvy will support the investments being made in technology and big data.

#3 – Reevaluating Processes

The industrial sector is reevaluating processes so they can plan to reduce costs. Some cost saving techniques include analyzing more data from previous quarters and relying on technology instead of employees to do some of the leg work. With 3-D printing, companies can build small-scale models and detect risks before proceeding with the full-scale project. Visibility to possible risks helps save money and keeps employees safe.

#4 – Augmented Reality

Augmented Reality can assist operators with assessing and making repairs to machinery with on screen step-by-step instructions. AR can also allow offsite repair technicians to see what the operators are seeing, even from another country, and help walk them through repairs. Smart devices have been used in the past few years for manufacturing and construction alike, but as the pandemic has shown us, technology is here to stay, and all industries are going to have to learn how to rely on it more.

#5 – Industrial Internet of Things (IIoT)

Internet of things refers to the connection of physical devices to the internet. The industrial internet of things are specific devices such as sensors, actuators, smart machines, and more. IIoT improves operation efficiency, new business opportunities, reduced downtime, and asset utilization.

“Construction is the fastest growing adopter of commercial drones,” due to the efficiency they’ve provided jobsites. Drones provide a great way to assess jobsites and construction without having to assign employees, which saves money and reduces risks. They provide a bird’s eye view of projects which can reveal information such as safety issues, materials being used on the job site, project progress, and more.

One third of manufacturing now utilizes smart devices and embedded intelligence. Sensors and indicators positioned on warehouse equipment can gather data, provide alerts if there are issues, and more. This valuable data can be used to predict failures and monitor machine health which will protect your facility from downtime. 98% of organizations report a single hour of downtime costs them over $100,000.

- Industrial security systems

- Energy consumption optimization

- Industrial heating, ventilation, and air conditioning

- Manufacturing equipment monitoring

- Asset tracking and smart logistics

- Ozone, gas and temperature monitoring in industrial environments

- Safety and health (conditions) monitoring of workers

- Asset performance management

- Remote service, field service, remote maintenance, and control use cases

- Smart factory applications and smart warehousing

- Predictive and remote maintenance

- Freight, goods, and transportation monitoring

- Connected logistics

Just like other big changes, technology cannot be implemented immediately, but it will define the success of your business. Manufacturing and construction industries will need to begin adopting available technology by prioritizing its impact. Technology will define the competitiveness of the industrial sector and moving forward without it could put you behind.